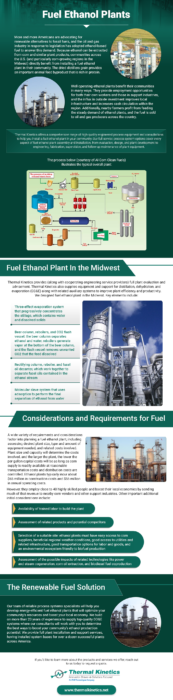

More and more Americans are advocating for renewable alternatives to fossil fuels, and the oil and gas industry in response to legislation has adopted ethanol-based fuel to answer this demand. Because ethanol can be extracted from corn and similar plant products, communities across the U.S. (and particularly corn-growing regions in the Midwest) directly benefit from installing a fuel ethanol plant in their community. The dried distillers grain provides an important animal feed byproduct that is rich in protein.

Well-operating ethanol plants benefit their communities in many ways. They provide employment opportunities for both their own workers and those in support industries, and the influx in outside investment improves local infrastructure and increases cash circulation within the region. Additionally, nearby farmers profit from feeding the steady demand of ethanol plants, and the fuel is sold to oil and gas producers across the country.

Thermal Kinetics offers a comprehensive range of high-quality engineered process equipment and consultations to help you install a fuel ethanol plant in your community. Our full-service process system options cover every aspect of fuel ethanol plant assembly and installation, from evaluation, design, and plant development to engineering, fabrication, supervision, and follow-up maintenance of plant equipment.

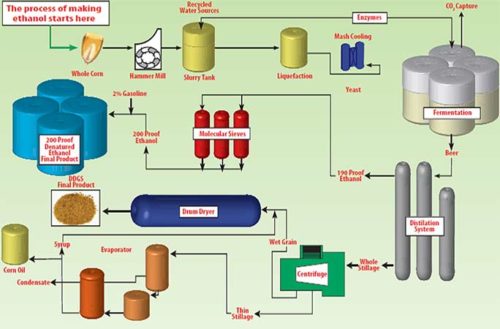

Below, we’ve outlined some of the main features of fuel ethanol plants, as well as a few points that investors and community members must consider before embarking on building their own ethanol plant. The process below (courtesy of Al-Corn Clean Fuels) illustrates the typical overall plant:

Fuel Ethanol Plant – Interactive Model

Thermal Kinetics provides (along with cooperating engineering service providers) full plant evaluation and advisement. Thermal Kinetics also supplies equipment and support for distillation, dehydration, and evaporation (DD&E) along with related auxiliary systems to improve plant efficiency and productivity.

The best way to understand how a fuel ethanol plant’s DD&E operation works is to see it in action. We based the interactive model below on an advanced biofuel production plant that we designed in the Midwest. Key elements include:

- Three-part evaporation system that progressively concentrates the stillage, which contains water and dissolved solids

- Beer column, reboilers, and CO2 flash vessel: the beer column separates ethanol and water, reboilers generate vapor at the bottom of the beer column, and the flash vessel removes unwanted CO2 that the feed dissolved

- Rectifying column, reboiler, and fusel oil decanter, which work together to separate fusel oils contained in the ethanol stream

- Molecular sieve system that uses adsorption to perform the final separation of ethanol from water

Interactive Fuel Ethanol Plant

At Thermal Kinetics, we’re committed to providing the best overall engineering support and solutions for the Fuel Ethanol Industry. A great deal of work goes into the conception, design, sourcing, and construction of a fuel ethanol plant and Thermal Kinetics is here to help.

Below is an interactive model of a Fuel Ethanol plant that our Process Engineers have designed for a project in the Midwest.

Hover over the different sections to learn more about each part of a standard Fuel Ethanol Plant.

Download Our Free eBooks on Advanced Biofuel Production

Thermal Kinetics seeks to be a resource in helping companies and communities meet their energy requirements through the use of advanced biofuel production. We offer a number of available resources on our website, including our Fuel Ethanol Library comprising of three eBooks:

- Simulation of Pressure Swing Adsorption in Fuel Ethanol Production Process

- Adsorption/Desorption of Water and Ethanol on 3A Zeolite in Near-Adiabatic Fixed Bed

- Modeling of PSA Process in Fuel Ethanol Production: Effect of Ethanol Co-Adsorption on the Performance

Accessing our Fuel Ethanol Library and fuel ethanol eBooks is quick, easy, and free. Don’t miss this opportunity—download your copy now.

Growth of Fuel Ethanol Plants in the US

Ethanol plants continue to be a viable and growing sector within the fuel production economy. Through 2018, fuel ethanol production capacity in the United States reached more than 16 billion gallons per year, amounting to 1.06 million barrels of ethanol per day. Additionally, the total listed capacity of operable ethanol plants increased by 5% between January 2017 and January 2018, translating to an increase of nearly 700 million gallons per year. Much of this increase was due to improved enzymes and other incremental improvements in operations as the industry matures. One negative result is depressed current ethanol prices due to an imbalance between supply and demand. In the long run the plants with the most efficient operations will survive and thrive. Demand is here to stay and best practices and efficiency will assure profitable businesses capable of riding out this challenge. Most ethanol plants are concentrated in the Midwest, with the Iowa, Nebraska, and Illinois ranking as the top ethanol-producing states, and recent years have seen continued growth in ethanol transportation infrastructure to serve increasing demand for energy-efficient fuel on both the East and West Coasts. As of June 2018, the United States had the nameplate capacity to produce 16.3 billion gallons of ethanol, refining 15.8 billion gallons per year, and as of December 2018, plans to construct or expand facilities that will produce an additional 395 million gallons. These factors and others ensure that the ethanol industry will continue to cement its place in the American fuel production sector. Communities that host ethanol production facilities will see greater economic growth due to improved job opportunities and an influx of new money from outside investment.

Considerations and Requirements for Fuel Ethanol Plants

A wide variety of requirements and considerations factor into planning a fuel ethanol plant, including assessing desired plant size, type and amount of equipment needed, and related costs involved. Plant size and capacity will determine the costs involved, and the larger the plant, the lower the per-gallon capital costs will be as long as corn supply is readily available at reasonable transportation costs and distribution costs are controlled. Ethanol plants typically incur about $65 million in construction costs and $56 million in annual operating costs. However, they employ close to 40 highly skilled people and boost their local economies by sending much of that revenue to nearby corn vendors and other support industries. Other important additional initial considerations include:

- Availability of trained labor to build the plant

- Assessment of related products and potential competitors

- Selection of a suitable site: ethanol plants must have easy access to corn suppliers, beneficial regional weather conditions, good access to utilities and related infrastructure, good transportation options for labor and goods, and an environmental ecosystem friendly to biofuel production

- Assessment of the possible impacts of related technologies like power and steam cogeneration, corn oil extraction, and biodiesel fuel coproduction

Site Selection Considerations

After deciding on a site, ethanol plant installers must conduct a prefeasibility evaluation that includes specific considerations such as:

- Assessing available feedstock as well as the ability to negotiate necessary supply agreements and contracts

- Evaluating the implications of transporting feedstock to the ethanol plant and transporting fuel from the plant

- Determining plant energy requirements, including assessing proximity to energy sources

- Conducting a thorough site evaluation determining the site’s geotechnical needs as well as rail and road access

- Ascertaining water requirements, including available access to possible water sources

- Assessing the plant’s potential economic and environmental impact on the chosen site

- Determining the necessary permits and approvals required by the local and regional government

It is often more economical to expand an existing plant; integrating a Thermal Kinetics process can improve efficiency of the plant both by the inherent TK DD&E application and by enhancing the existing plant operations and fermentation performance. The existing plants already have the personnel and the established operational practice and infrastructure. Thermal Kinetics can assist in the evaluation of such expansion plans and optimize overall plant performance.

The Renewable Fuel Solution

Our team of reliable process systems specialists will help you develop energy-efficient fuel ethanol plants that will optimize your community’s resources and boost your local economy. We build on more than 20 years of experience to supply top-quality DD&E systems where our consultants will work with you to determine the best ways to boost your community’s ethanol production potential. We provide full plant installation and support services, having installed system bases for over a dozen successful plants across America. We’ve patented groundbreaking designs for improved molecular sieves, improved product purification techniques, and unique systems integration, and we’re in the process of developing new methods for advanced biofuel production. If you’re looking for expert consulting on your next custom-designed ethanol plant proposal, Thermal Kinetics has a great deal to offer. Download our eBooks, view our interactive model, and if you like what you see, contact us to request a quote today. We are ready to help fuel your economy.

Working with Thermal Kinetics

Fuel ethanol plants should be designed to ensure reliable performance and cost efficiency. Working with an experienced process systems specialist like Thermal Kinetics will allow you to optimize your fuel ethanol plants and enhance product quality. From supplying complete DD&E systems to developing proprietary modeling software, our process experts know exactly which solutions are best for those in the Renewable Fuels industry. We’ve been working in this field for nearly 20 years, and our efforts have resulted in not one but four fuel ethanol processing patents: improved molecular sieves, product purity enhancements, and unique systems integration as well as continuing development of two more pending patents for advanced biofuels production. To learn more about how Thermal Kinetics can assist with your custom plant design, contact us today.