Distillation, Dehydration & Evaporation (DD&E)

Comments Off on Distillation, Dehydration & Evaporation (DD&E)In a conventional dry mill ethanol plant, the central processing area and one of the largest users of energy is the Distillation, Dehydration, and Evaporation (DD&E) system. Traditionally, ‘beer’, the source of the ethanol, is produced in a fermentation process using very large vessels.

From there it is pumped into a Beer Stripping Column where the ethanol is initially extracted using steam or vapor as the heat source. The dilute ethanol stream discharged from this column will be further refined, before being Dehydrated using Molecular Sieve technology in a Pressure Swing Adsorption (PSA) process.

The secondary column, or Ethanol Rectification Column (ERC), will generate a rich, 92% w/w ethanol overheads stream, which will then be fed to the PSA system. The molecular Sieves will dehydrate the incoming feed from the ERC to produce a 200 Proof ethanol product that is suitable for blending with gasoline.

Whole Stillage discharging from the bottom of the Beer Stripping Column is fed to a series of centrifuges (solid/liquid separation) whereby undissolved solids are removed. The liquid discharge from the centrifuges, which contains dissolved solids, is sent to an evaporator whereby the dissolved solids are concentrated to 30%-35% w/w. The solid rich effluent from the evaporation system is termed ‘Syrup’.

The undissolved solids from the centrifuge and the syrup are combined and used as either ‘Wet’ or ‘Dry’ cattle feed:

- ‘Wet’ Feed is used on an ‘As Is’ basis; it’s termed Wet Distillers Grain with Solids or WDGS in the industry. ‘Wet’ Feed has a short shelf life and must be used quickly to prevent biological activity.

- For a longer shelf life product, the combined streams are sent to a dryer to remove the majority of the water. The product from the dryer is termed Dried Distillers Grain with Solids or DDGS.

With over 35 years of experience designing state-of-the-art Ethanol DDE Facilities, Thermal Kinetics (TK) has developed and patented various process enhancements, to improve the functionality and energy efficiency of conventional plants that are currently in operation. These enhancements include:

- Lower ‘Backset’ or recycle to Fermentation; 57.3% Reduction in flow,

- Enhanced Removal of Fusel Oils,

- Lower Energy Usage;

- 21% lower usage based on current ethanol feed concentrations of (12%-13½% w/w),

- 31% lower usage when an enhanced 15% w/w ethanol feedstock is achieved,

- Improvements in Condensate Reuse; 56.5% gain in Condensate Recovery,

- Improvements in Processing Whole Stillage;

- Increased Solid Concentrations feeding the centrifuges

- 20% reduced load on the centrifuges,

- Enhanced Thin Stillage concentrations,

- Lower Operating Temperatures within the Evaporation System;

- Reduces Fouling, which leads to

- Longer production campaigns between maintenance shutdowns.

Based on these enhancements, TK has improved the overall efficiency of the DDE process as illustrated in the table below. The numbers illustrated are based on a 50MM gallon/annum ethanol production rate and a 13.1% ethanol concentration in the feedstock to the Beer Stripping Column.

| TK PATENTED PROCESS | CONVENTIONAL TECHNOLOGY | |

| TOTAL STEAM REQ’D | 56,210 LB/HR | 71,525 LB/HR |

| EQUIVALENT HEAT | 49.8 MM BTU/HR | 63.37 MM BTU/HR |

| WHOLE STILLAGE FLOW | 247,063 LB/HR | 296,564 LB/HR |

| WHOLE STILLAGE CONC | 16.22 WT% | 13.51 WT% |

| CENTRIFUGE LOAD | 430 GPM | 529 GPM |

| EVAP FEED | 243 GPM @ 8.65% | 232 GPM @ 7.03% |

| RECYCLE TO FERMENTATION (BACKSET) | 87.7 GPM | 205.4 GPM |

| FUSEL OIL DECANTER | YES | NO |

| PROCESS CONDENSATE FOR RECYCLE RECOVERED | 123,969 LB/HR

247.9 GPM |

79,187 LB/HR

158.4 GPM |

| 1st EFFECT EVAP TEMP (F) | 152° | 199° |

| 2nd EFFECT EVAP TEMP (F) | 127° | 185° |

| BEER COLUMN BOTTOM (F) | 203° | 185° |

Learn more by downloading our technical paper Simulation of Pressure Swing Adsorption (PSA) in Fuel Ethanol Production Process. Click here or below to download.

Want more detailed information? Contact us and one of our process experts get back to you.

How to Choose the Best Evaporator for Your Application

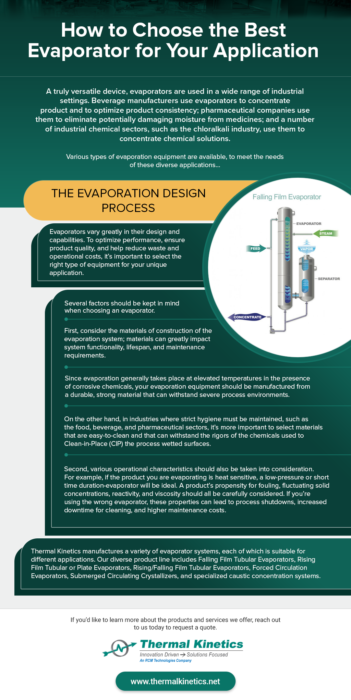

Comments Off on How to Choose the Best Evaporator for Your Application A truly versatile device, evaporators are used in a wide range of industrial settings. Beverage manufacturers use evaporators to concentrate product and to optimize product consistency; pharmaceutical companies use them to eliminate potentially damaging moisture from medicines; and a number of industrial chemical sectors, such as the chloralkali industry, use them to concentrate chemical solutions.

A truly versatile device, evaporators are used in a wide range of industrial settings. Beverage manufacturers use evaporators to concentrate product and to optimize product consistency; pharmaceutical companies use them to eliminate potentially damaging moisture from medicines; and a number of industrial chemical sectors, such as the chloralkali industry, use them to concentrate chemical solutions.

Various types of evaporation equipment are available, to meet the needs of these diverse applications…

Factors to Consider During Evaporator Selection

Evaporators vary greatly in their design and capabilities. To optimize performance, ensure product quality, and help reduce waste and operational costs, it’s important to select the right type of equipment for your unique application. Several factors should be kept in mind when choosing an evaporator.

Evaporators vary greatly in their design and capabilities. To optimize performance, ensure product quality, and help reduce waste and operational costs, it’s important to select the right type of equipment for your unique application. Several factors should be kept in mind when choosing an evaporator.

First, consider the materials of construction of the evaporation system; materials can greatly impact system functionality, lifespan, and maintenance requirements.

Since evaporation generally takes place at elevated temperatures in the presence of corrosive chemicals, your evaporation equipment should be manufactured from a durable, strong material that can withstand severe process environments.

On the other hand, in industries where strict hygiene must be maintained, such as the food, beverage, and pharmaceutical sectors, it’s more important to select materials that are easy-to-clean and that can withstand the rigors of the chemicals used to Clean-in-Place (CIP) the process wetted surfaces.

Second, various operational characteristics should also be taken into consideration. For example, if the product you are evaporating is heat sensitive, a low-pressure or short time duration-evaporator will be ideal. A product’s propensity for fouling, fluctuating solid concentrations, reactivity, and viscosity should all be carefully considered. If you’re using the wrong evaporator, these properties can lead to process shutdowns, increased downtime for cleaning, and higher maintenance costs.

Second, various operational characteristics should also be taken into consideration. For example, if the product you are evaporating is heat sensitive, a low-pressure or short time duration-evaporator will be ideal. A product’s propensity for fouling, fluctuating solid concentrations, reactivity, and viscosity should all be carefully considered. If you’re using the wrong evaporator, these properties can lead to process shutdowns, increased downtime for cleaning, and higher maintenance costs.

Thermal Kinetics manufactures a variety of evaporator systems, each of which is suitable for different applications. Our diverse product line includes Falling Film Tubular Evaporators, Rising Film Tubular or Plate Evaporators, Rising/Falling Film Tubular Evaporators, Forced Circulation Evaporators, Submerged Circulating Crystallizers, and specialized caustic concentration systems.

Learn More

To learn more about evaporators and how to select the best type for your project, download our free Evaporator Selection Guide.