Featured Chemical Industry Project:

GS Caltex Acid Recovery Unit

Thermal Kinetics (TK) was first contacted in 2015 by GS Caltex (GSC is jointly owned by GS Holdings and Chevron) to provide an evaporation system to recover sulfuric acid for their first bio-butanol plant (see GSC Bio-butanol/ Bluefire Renewables technology below).

Project Design

- The TK system is designed to re-concentrate a 15% by weight sulfuric acid feedstock containing residual sugars.

- The TK separation process is designed with specific mechanical and control features to minimize the impact of foaming.

- The 75% H2SO4 product being delivered from the evaporator is re-introduced into a biomass process to hydrolize cellulose.

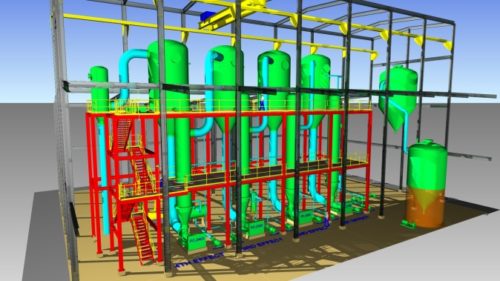

The acid concentration process is centered around a falling film, single-effect evaporator. The separation of H2SO4 and water is straightforward, but the design of the system was complicated by the wide array of materials required to withstand the corrosiveness of the acid at elevated temperatures and high vacuum (glass-lined vessels, PTFE lined pipe/pumps and graphite heat exchangers). Overall, the project was a success, with the modularized equipment being delivered on-time over a period of 45 weeks. The equipment system shown in the picture was export boxed (main module) with auxiliary subassemblies and components shipped in two additional standard 40’ sea containers. The re-assembly plan is illustrated in accompanying 3D exploded drawing.

GS Caltex Bio-butanol History:

Thermal Kinetics has been a technology and systems supplier to Bluefire Renewables for close to twenty years. Bluefire has developed and matured a wide range of technologies to process biomass into renewable ethanol and other chemicals, while recovering lignin and generating power and heat from the processes. Thermal Kinetics has provided to Bluefire acid recovery systems (ARU) and ethanol distillation and dehydration technologies. Three years ago GS Caltex began development of a bio-butanol facility based on Bluefires’ patents and technology advances

Contact Us About Your Project

Other Chemical Industry Projects include:

Sodium Sulfate Production from Ore Dissolution and Purification Followed by Energy Efficient Four Effect Crystallization

In this project, the location in Mexico had a very limited water supply, so the challenge was to prepare and concentrate the 30% solution of sodium sulfate while minimizing the amount of water that the plant uses. Discover how we overcame this challenge and produce results for this facility.

Learn More

Modular, Double Effect Caustic Soda (NaOH) Evaporator

| Location: Foley, FL (fabricated in Buffalo, NY) |

Date Started: February 2, 2012 |

Date Completed: December 3, 2012 |

Thermal Kinetics provided:

- Engineering Services

- Contractor for Equipment

|

|

|

Project Details

Thermal Kinetics provided engineering services for the initial proposal development, and after the purchase order was awarded, Thermal Kinetics was contracted for detailed design. Services provided included 1) Process Flow Drawing, 2) P&IDs, 3) Equipment General Arrangement Plan and Elevation Drawings, including piping, 4) Skid Assembly Drawing, 5) Structural Design and PE Stamped Drawings, 6) Piping Details and Isometrics as needed, 7) Foundation Anchor Bolt Plan and Concrete Pad Size Requirements, 8) Equipment list and specifications (TEMA data sheets, vessel outline drawings, and pump datasheets), 9) Lists – Valves, Instruments, Specialty Items, Line, Instrument Data Sheets Completed with Process Data (ISA format), 10) Instrument Device Location Plan, 11) Instrument Loop Schematics, 12) Electrical Single Line Drawings, and 13) Functional Description of Operation. Operating field manuals were supplied, as well as support for commisioning and startup.

Calcium Chloride Plant Retrofit Evaluation

| Location: St. Gabriel, LA |

Date Started: August 5, 2010 |

Date Completed: May 2, 2011 |

Competencies Applied:

- Integrated Process Facilities

|

Thermal Kinetics Patents & Trade Secrets Applied:

- Calcium Chloride processing experience and techniques for dealing with such fouling solutions.

|

|

Project Details Customer acquired a calcium chloride production facility that was closed due to excessive fouling of major equipment items from calcium sulfate. In 2006 Thermal Kinetics had been hired to prepare a report on the plant operational problems to establish root causes and potential remedies. The plant process reacted spent HCl and limestone, applied hydroxide chemistry to remove magnesium and other metals, filtered, then concentrated the resulting dilute calcium chloride solution by evaporation. This process did not sufficiently remove sulfates and the evaporator design was not correct for this application. For Salexus Thermal Kinetics developed a full retrofit plan based on lab testing including the cost estimate for this retrofit. New evaporation equipment and upgraded filtration systems were developed for this work.

Propyl Sorbitol Concentrator

| Date Started: July 18, 2011 |

Date Completed: July 22, 2012 |

|

Project Details Thermal Kinetics provided engineering services to supply an evaporator to concentrate Propyl Sorbitol, an alcohol sugar, from 35% concentration to 80% concentration (20% water). After the purchase order was awarded, Thermal Kinetics was contracted for detailed design. Services provided included:

- Process Flow Drawing,

- P&IDs,

- Equipment General Arrangement Plan and Elevation Drawings, including piping,

- Skid Assembly Drawing,

- Structural Design and PE Stamped Drawings,

- Piping Details and Isometrics as needed,

- Foundation Anchor Bolt Plan and Concrete Pad Size Requirements,

- Equipment list and specifications (TEMA data sheets, vessel outline drawings, and pump datasheets),

- Lists – Valves, Instruments, Specialty Items, Line, Instrument Data Sheets Completed with Process Data (ISA format),

- Instrument Device Location Plan,

- Instrument Loop Schematics,

- Electrical Single Line Drawings, and

- Functional Description of Operation. Operating field manuals were supplied, as well as support for commissioning and startup.

Quinoline and Toluene Distillation

| Date Started: October 26, 2011 |

Date Completed: October 15, 2012 |

|

- Distillation and Separations

Project Details An equipment supplier to our customer partially completed construction of distillation systems for separation of Toluene and Quinoline and producing a bottoms residue of nanopartical carbon. Thermal Kinetics was contracted to evaluate the design and provide a report on what was required to complete the project. After issuing the report TK prepared PFDs and stream tables forming the process basis for the facility, designed and specified all equipment to be added to the facility including stripping column, reboiler, new pumps, and new heat exchangers as required. After the revised design documentation TK assisted during the construction and startup phases.

Sodium Sulfate Ore Processing and Crystallizer

| Date Started: March 14, 2013 |

Date Completed: March 25, 2014 |

|

Competencies Applied:

- Crystallization and Integrated Facilities

|

Thermal Kinetics Patents & Trade Secrets Applied:

- Calcium Chloride processing experience and techniques for dealing with such fouling solutions.

|

|

Project Details The project included mining sodium sulfate rich ore, transporting the ore to a processing facility, dissolving the ore, clarifying, and purifying a sodium sulfate saturated solution, then ussing a four effect evaporative crystallization train to produce a purified crystal. The crystallizer slurry was centrifuged and dried. Thermal Kinetics completed the plant wide material and energy balance, fines removal system, and dissolving/clarifying subsystems. Thermal Kinetics also supplied the equipment, large bore piping, field instruments and valves for the crystallizer portion of the plant. Forced circulation evaporator heaters were constructed in titanium on the tube side and duplex stainless steel on the shell side. Crystallizer bodies, pumps, piping, and all other liquid contact surfaces were duplex stainless steel. The large circulation rates required use of 24 inch diameter axial flow pumps.