For almost two decades, Thermal Kinetics has served as a full-service process equipment, engineering, development, and design firm, helping customers to optimize ROI on even the most unique operations.

Our innovative and solutions-focused team integrates patented technology and energy-saving techniques to deliver sophisticated processing systems to virtually any industry. Our product line is fully customizable and includes equipment in the following areas:

Fuel Ethanol Plants

At Thermal Kinetics, we’re committed to providing the best solutions to your ethanol plant energy requirements. A great deal of work goes into the conception, design, sourcing, and construction of a fuel ethanol plant.

Before beginning the process, there are several important factors to consider, including:

- Plant size and cost

- Construction labor availability

- Assessment of co-product markets

- Site selection

- Availability of capable operators and plant staffing

Adsorption Equipment

Using Pressure Vacuum Swing Adsorption (PVSA) on molecular sieves, our team conducted extensive research on the optimization of fuel ethanol dehydration. With these findings, we developed robust software to model performance, identify improvement opportunities, and upgrade plants to operate at adsorption pressures as low as 20 PSIA.

Associated equipment includes:

- Two Bed MSUs

- Three Bed MSUs

- Performance Modeling Graphs

See Adsorption Equipment

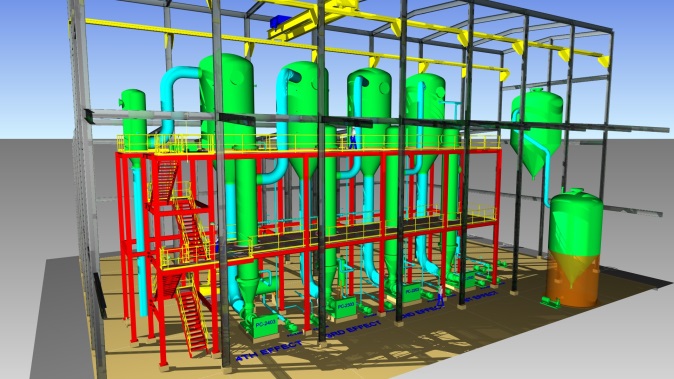

Evaporation Equipment

Our evaporators, available in broad range, high efficiency configurations, evaporate volatile solvents and concentrate non-volatile solutes from solutions. The recovered solvent, oftentimes water, can then be recycled back into the system or used throughout another processing operation.

Associated equipment includes:

- Falling Film Tubular Evaporators

- Rising Falling Film Tubular Evaporators

- Rising Film Tubular Evaporators

- Forced Circulation Evaporators

- Internal Pump Forced Circulation Evaporators

- Plate Stripping and Evaporation Systems

- Caustic Specialized Concentration Systems

See Evaporation Equipment

Distillation Equipment

We offer a variety of distillation services to separate component substances through mass transfer. By employing process modeling, lab testing, and prototyping, we can find the optimal solution for every customer — from smaller standard sizes to completely customized systems.

Associated equipment includes:

- Trayed Columns

- Packed Columns (Structured and Random Packing)

- Scrubbers and Adsorption Systems

- Integrated Distillation Systems

- Energy Integrations Using Double Effect and Mechanical Vapor Recompression

See Distillation Equipment

Crystallizer Equipment

Our crystallizers separate solids from solutions in the form of crystalline structures through heat and mass transfer. The high purity crystals are then removed from the system while the remaining purified solvent can be cycled back through or passed on to fulfill subsequent processing operations.

Associated equipment includes:

- Draft Tube Crystallizers

- Submerge Circulating Crystallizers

See Crystallizer Equipment

Specialty Process Systems

Outside of our vast standard equipment offering, our experienced team of designers, developers, and engineers can assess your unique operations to build optimized systems tailored to your particular needs.

Past work includes:

- Gas/Liquid/Solids Reactor

Limestone/HCl Reactor for CaCl2 Production

- Flake Caustic Soda Systems

- Flake Calcium Chloride and Potassium Chloride Systems

- Citric Acid Production Systems

See Special Process Systems

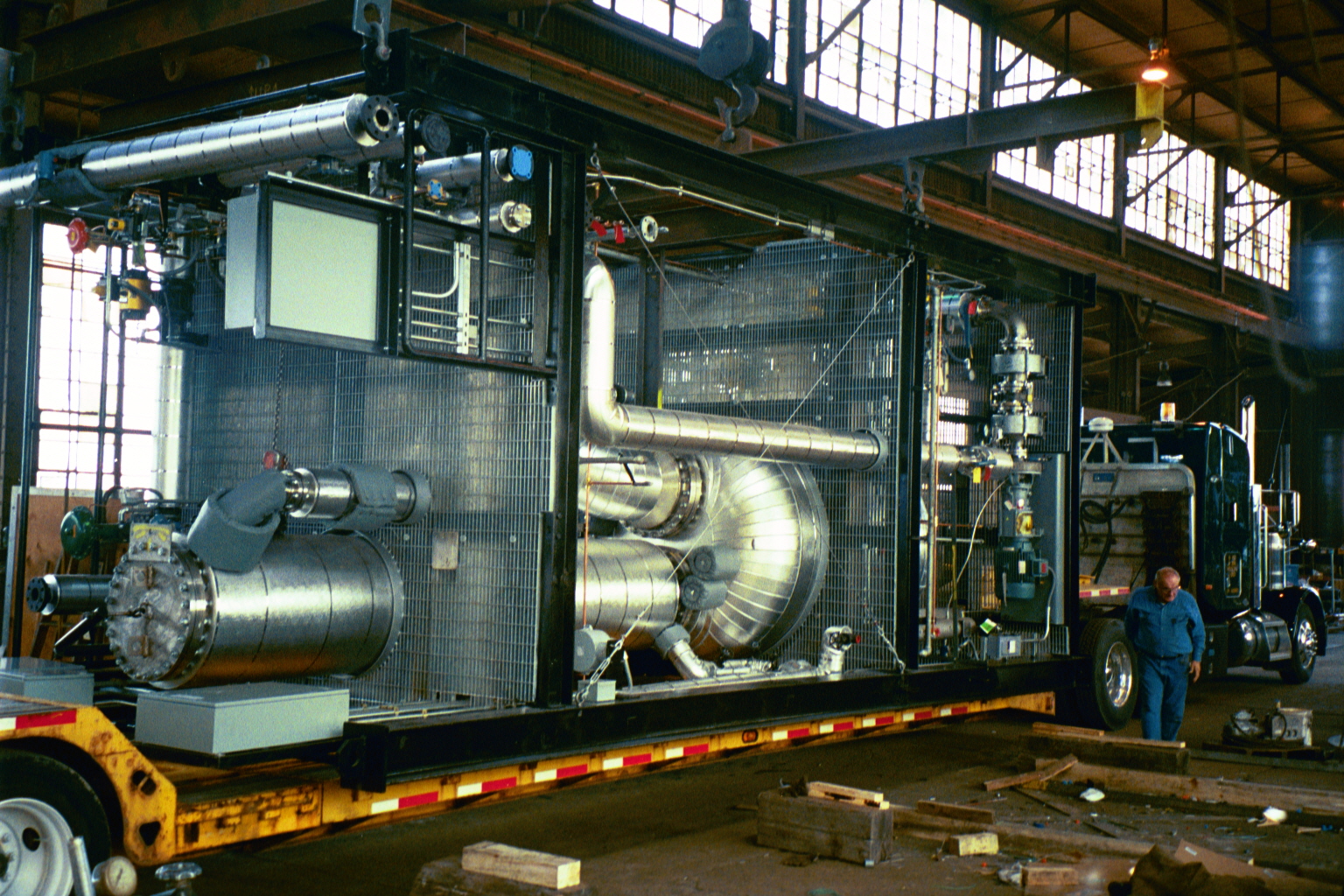

Modular Systems

All of our products and equipment can be produced as modular units or skids — built offsite at our facility and delivered directly to your plant for easy, expedient installation. Our team can reconfigure components of any system to fit within a steel frame that meets your plant’s mechanical specifications and architectural layout requirements.

Past work includes:

- Double Effect Caustic Soda Evaporator

- Ethylene Glycol Purification System

- Sorbitol Concentration Skid

- Cellulosic Fuel Ethanol Dehydration Unit

- Double Effect Gelatin Finish Evaporator